New Updates!

I've been continually updating the main post with updates, but I can't believe the last detailed update was back in October.

While it's been a crazy few months I've been making good progress with this car.

Transmission Overhaul

As mentioned in the last update, the passenger side inner CV was stuck in the differential (due to a faulty snap-ring). While the transmission was apart (so I could inspect it), I discovered that the internals were not made by Hewland even though the case has a Hewland engraving. I confirmed my findings with a contact I have at Hewland and was more or less left scratching my head on what brand this gearset was... The next part (COTA - 24h event) answers this...

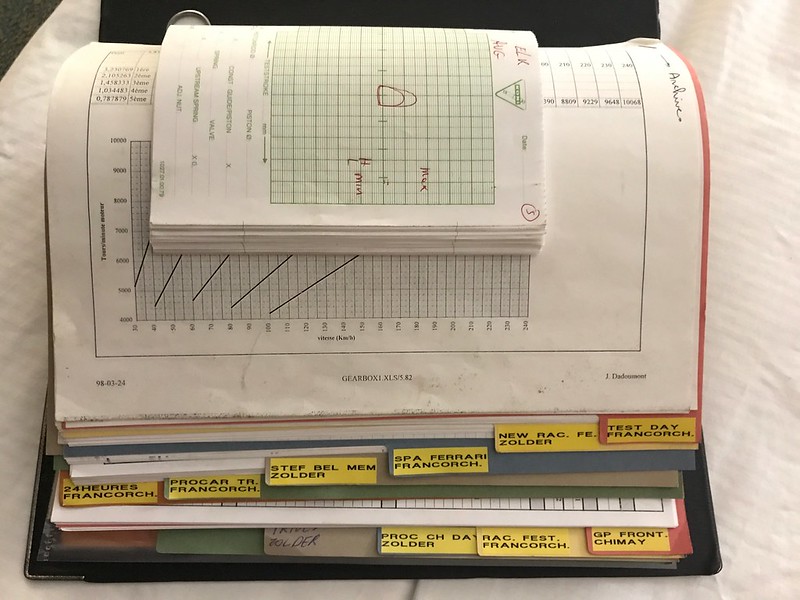

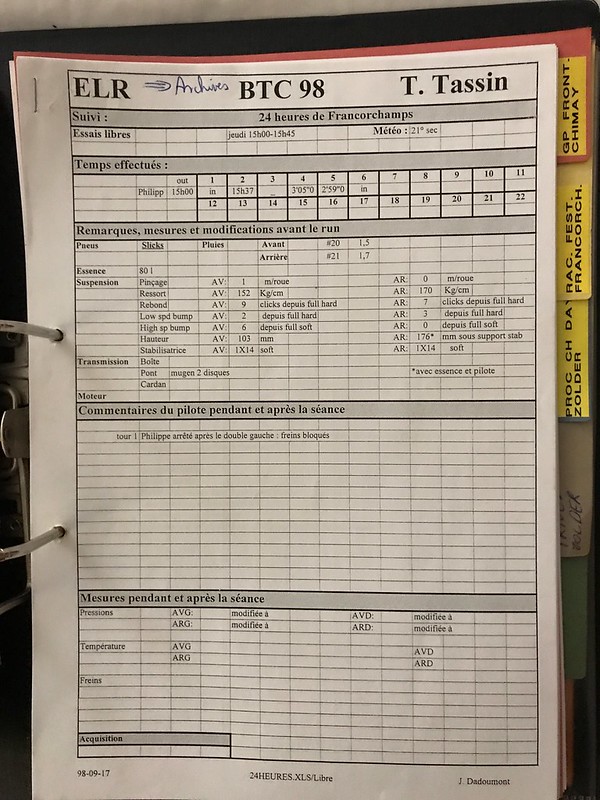

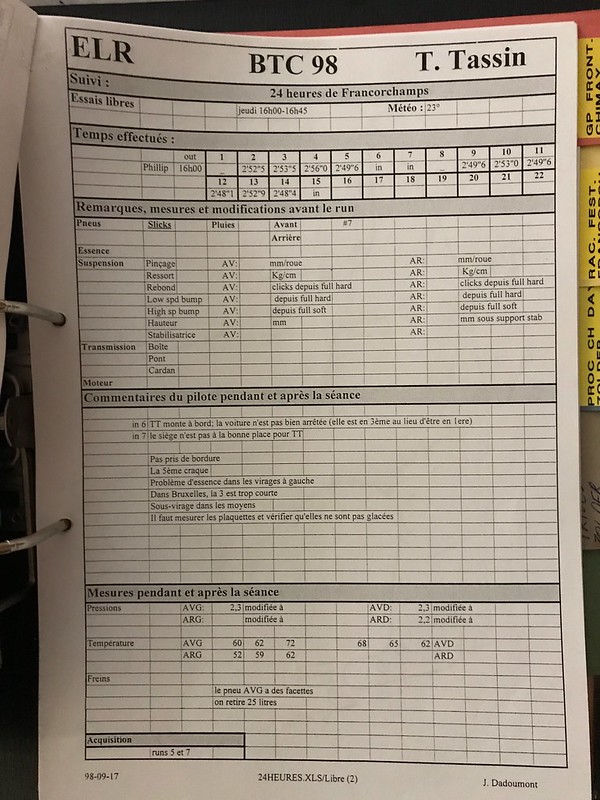

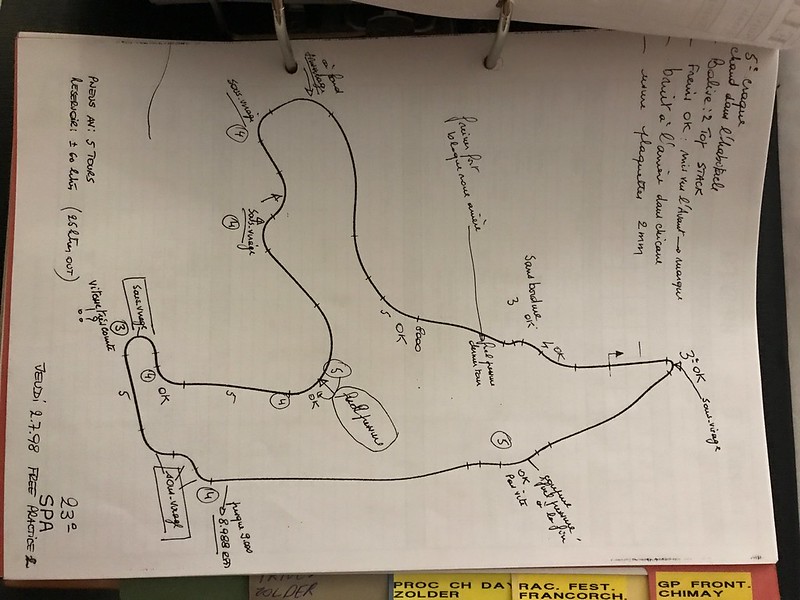

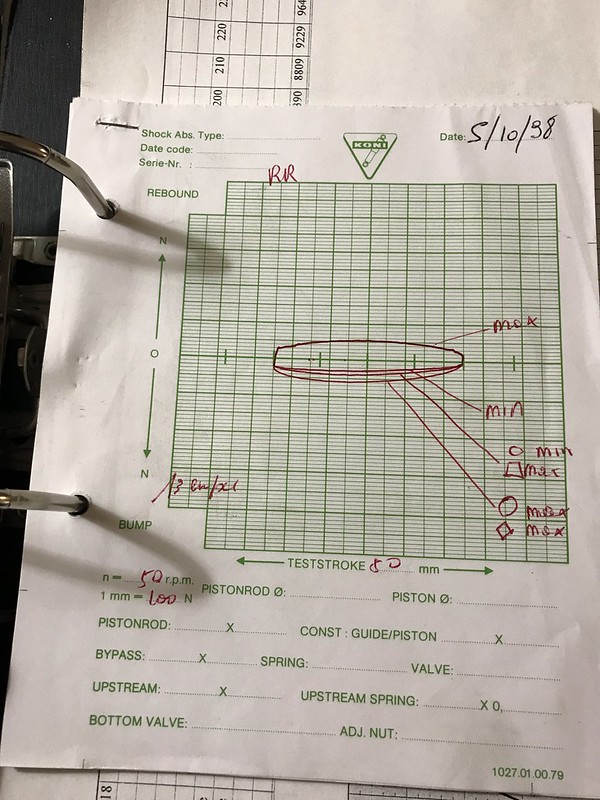

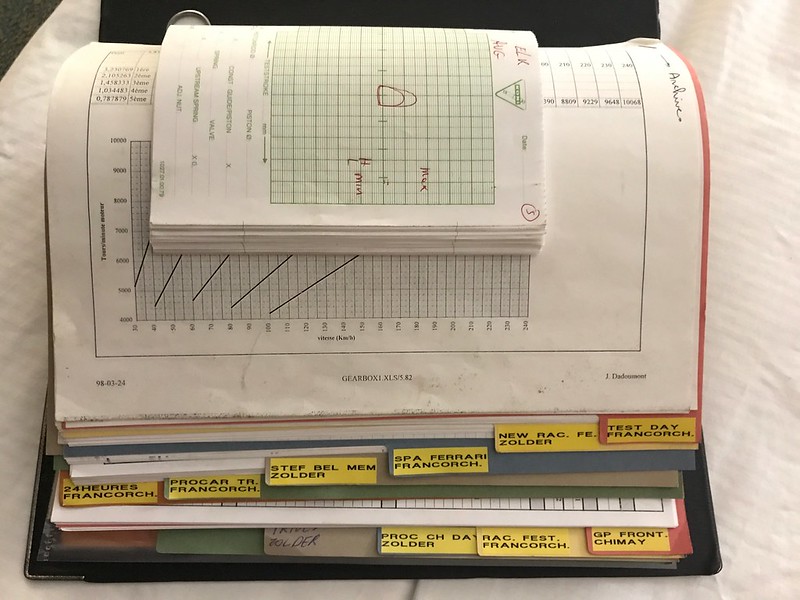

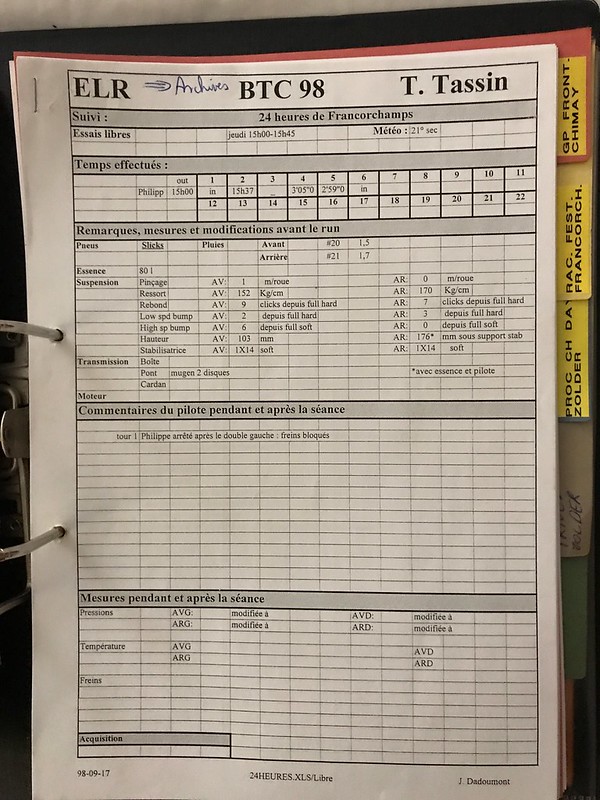

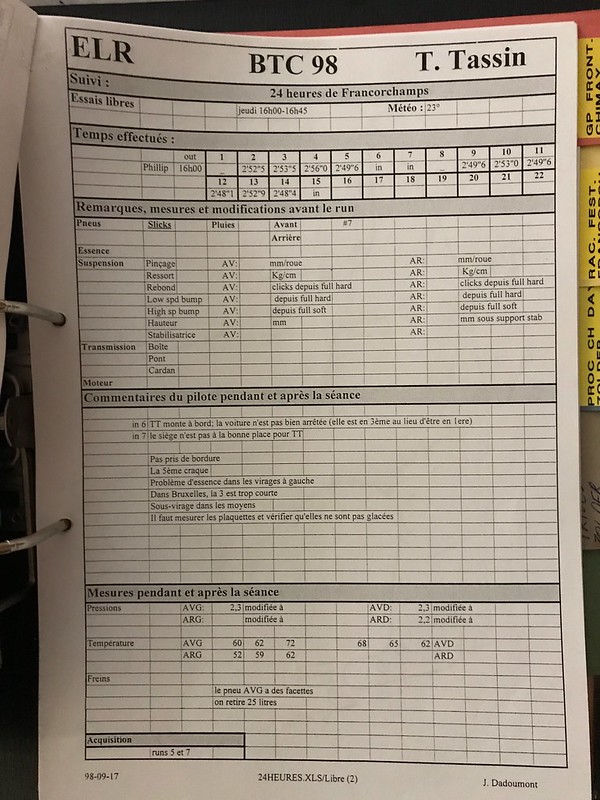

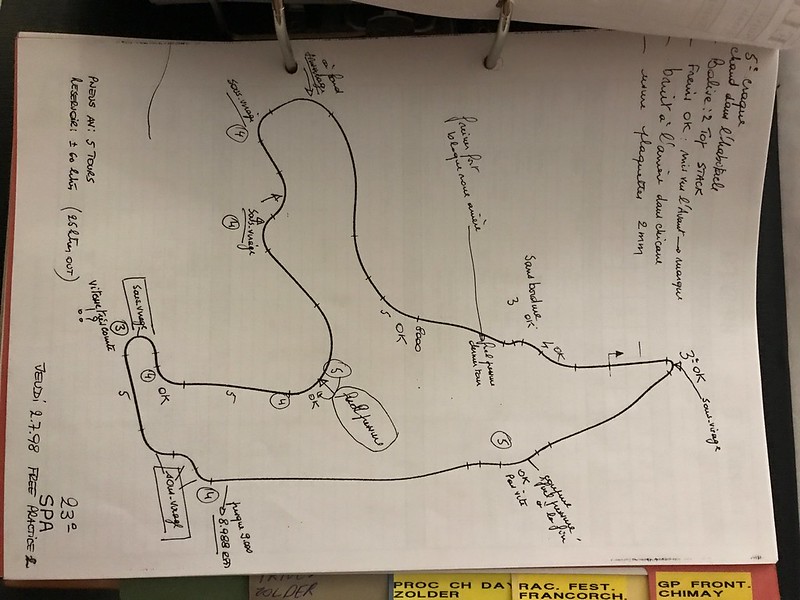

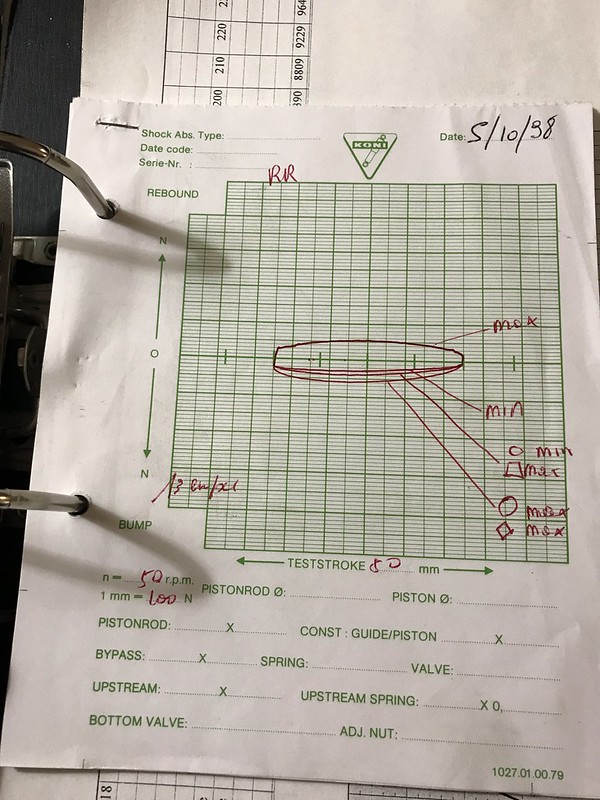

COTA - 24h event & vehicle racing binder

Back in August while speaking with Mark Hein, he informed me that Marc Vanderghen (owner/team manager of ELR) was going to be at COTA to oversee the VDS Racing Adventures MARC V8 team and invited both of us to him (both Mark and Marc are very good and old time friends - going back to when Mark raced my yellow car at Spa in 2000). Obviously I had go and boy was it amazing (my first 24h event). First off, Marc showed me the ins/outs of 24h racing and over seeing a race team, the strategy and drivers. Marc is very well known in Europe and most of the employees that work on his teams do so because he has a long lineage of training his personnel so they can go on to work for top race teams in Europe (Mercedes AMG, Aston Martin, Porsche, Formula 1, etc...). Second, Marc surprised me with a HUGE binder on my car (the #7 Thierry Tassin ELR/Honda/Foss-Tech). This binder containing all the engineering notes, driver notes, suspension dynos, corner weight, track maps, engine/transmission settings, etc... EVERYTHING. It covered the entire 1998 Procar season and they documented everything in amazing detail. It's in French of course but thankfully some of that language is coming back to me. Google translate can help fill in the gaps. This binder is absolutely key to documenting it's history. He also heard I was trying to locate the air lance adapter for the air jacks and brought me a spare connector. He also looked over most of my pictures and pointed out several items/details I didn't know about. For example, the aluminum dead foot rest was made by his brother by hand. The suspension pick up points and settings were specifically optimized for Thierry Tassin as he was a four time BMW factory champion and was very particular how his car should feel. The transmission internals were indeed not Hewland but rather were made by WTI, a high-end French transmission manufacture that's no longer in business. The WTI gear box was pinnacle of gear boxes at the time and were VERY expensive because of the extensive amount of machining they'd do. During the 1998 Procar series the car used a Hewland gear box because the ratio's met Super Production specifications (had to be within 2% of factory ratios) except for a more or less unlimited final drive ratio. The WTI gear box uses a Group N ratio which was only allowed for the Group N class. The Group N class was underneath Super Production but because Group N cars were less exotic, they were allowed to use more aggressive gear ratios to compensate for the performance gap. Anyhow, when Marc sold the car to Jose Fontes in Portugal, he supplied them with a Group N gearbox because Portuguese Touring car rules allowed for those ratios. As for the Hewland case, Marc used a spare case from a Hewland gear set that was damaged. The case is in fact one of the original cases for the car. The spare Hewland gear sets and parts I got from Mark Hein (for my yellow car) are the original gear sets for this gear and Marks yellow car. Small world. Unfortunately, because WTI no longer exists, Marc advised that I get limit the use of this gearbox until I can find a machine shop to make spares.

Interesting fact: José Close (the older gentlemen kneeling on the ground with glasses and next to the guy in the florescent vent - on his left) drove the #41 Team VZM Honda Integra Type R in the 1998 24h of Spa. They competed against my car but had the motor fail in the last hour or two of the race.

Mark Hein - builder/driver of my yellow car(left), Marc Vanderghen - builder/team manager of this car (center) and me (right)

New sequential transmission

New sequential transmission

During my conversation with Marc V, he told me that he recommends I look into a sequential gear box for the gear. While it's not within the original 1998 Procar specifications, it is a transmission they used for certain events that allowed for it. So what did I do? I located a full sequential gearbox with a mechanical shifter and optional pneumatic actuated paddles and computer control system. My friends at DMRR in the UK assisted with the custom setup and by Christmas I received the transmission. The ratios are between 99-99.8% of the WTI ratios and the LSD is a 1.5way plate style like the WTI. It should feel exactly the same expect for the near seamless and bulletproof shifting from the sequential design and electronically controlled ignition cuts and throttle blipping.

Suspension overhaul

Suspension overhaul

While the transmission was out of the car, I decided to blueprint and overhaul the original Penske suspension. Angelo and the folks over a Anza (who previously blueprinted and overhauled the Moton's on the yellow car) took care of everything. The baseline shock dynos were actually pretty good, however, the rear canisters needed new bladders and seals and the fronts needed new seals. After some new shims, valve stacks and hose, the suspension fully blueprinted and dyno'd again before shipping them back. The process took about two months due the high level of everything being blueprinted.

Leaky & stuck pistons - front calipers

Leaky & stuck pistons - front calipers

While I was waiting on the suspension I discovered the front calipers were starting the leak fluid out of the piston seals and the pads were wearing unevenly. I also noticed the brakes were very inconsistent during the last track day. The calipers were likely last serviced back in 1998/1999 so after 14yrs sitting and two years racing, the seals finally were starting to go. Previously on the yellow car I rebuilt the calipers myself using new parts from AP Racing, however, a recent discovery reveled that Essex (USA - AP Racing distributor) will rebuild calipers for a VERY reasonable price. To help me pick and choose my battles, and manage the limited amount of free time I have, I decided to let them do the overhaul. They did a before and after pressure test, fully blueprinted the calipers and inspected everything for racing fatigue (common with old/historic parts). Thankfully everything checked out and only the seals and bleeders needed to be replaced. The process took about two or three weeks.

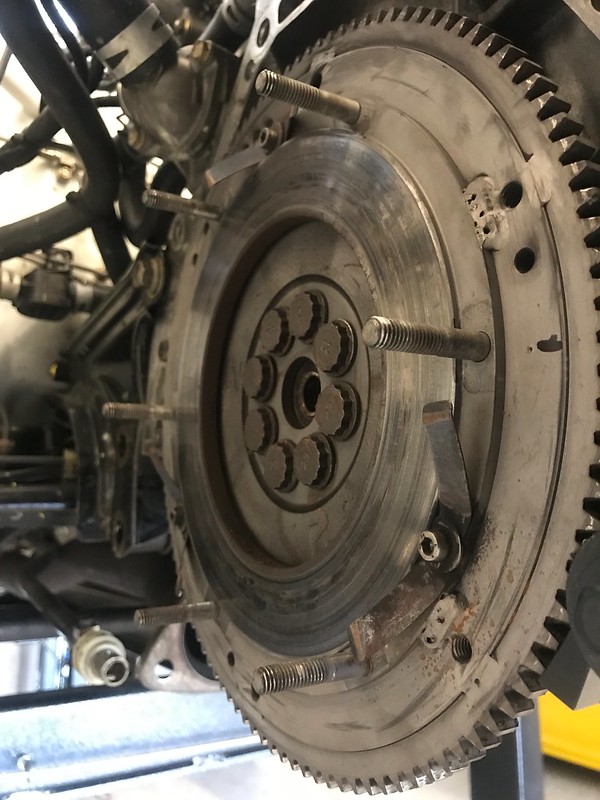

New clutch parts & axles

New clutch parts & axles

Since I was in the process of overhauling/replacing the transmission, I decided to replace the clutch system. A new clutch master cylinder, clutch slave, fork, throwout bearing, pilot bearing, flywheel, pressure plate and clutch disc were installed. Nothing too crazy since I won't need to use the clutch for gear changes. Also since the original axles were starting to leak and a CV was damaged from the bad snap-ring, I upgraded the axles with Driveshaft shop Stage 2 units with the road race upgraded (high-temp grease, polished internals, upgraded bearings, and vented boots). It's the same axles I use on the yellow car.

New OMP carbon seat

While the old seat was perfectly good, I wasn't able to adjust it to a position that felt good for me. The side-to-side head protection interfered with the roll cage cross bar which wouldn't allow me to reach the pedals because the seat was too far back. After doing a track day with a sweatshirt stuffed behind me I decided a new seat would be the only option. Because OMP was the original brand for the car, and because the original design is no longer being made (OMP King), I decided to go with a similar design that also had the benefit of being a lot lighter. The OMP WRC-R with a full carbon shell was selected and a very lightweight FIA approve mounting system was installed. After about eight hours adjusting everything I think it got it pretty damn good, although I may try to how one more notch lower later on. Also a weight loss of 10lbs was realized with the seat swap. The harnesses will also be replaced but once I figure out if I want a regular 3" harness or go with a 2" HNS/HANS only version.

Power steering system/pump failed

Power steering system/pump failed

During the last track day I noticed some fluid was coming out of the power steering reservoir. It's not uncommon for that to happen, especially during high G loaded corners and/or if the reservoir fluid level is too high. I didn't think much about it outside of keeping an eye on it. Fast forward a few months and while on the dyno (tuning the new sequential transmission) I noticed the more fluid was leaking. While the car was running I remove the red reservoir cap and noticed the fluid was foam a lot. This is typically a sign of a failing power steering pump (bad seals/bearings). Next weekend I'll be overhauling the entire system, the pump, hoses, etc...

I also added a lot more content to the first post in the this thread. Several friends and individuals in Europe have been sending me media content and magazine articles on my car. It's amazing how much material I keep discovering.