Re: Resurrection: 1998 Belgian Procar - Thierry Tassin ELR/Honda/Foss-Tech #7 race car

Posted: Mon Oct 23, 2017 3:19 pm

I've been updating the process timeline on the main post, however, I figured it would be easier to add detailed progress pictures within the thread. Below are some recent updates:

Doweled cylinder head/intake manifold

As part of getting every ounce of power from this motor ELR/NBE doweled the cylinder head and intake manifold for perfect gasket alignment. Both the head and manifold showed signs of porting but it wasn't anything extreme as the FIA limited the shape and opening size within 2-4% of stock. I didn't snap a picture but even the throttle body shaft size was machined for improved airflow.

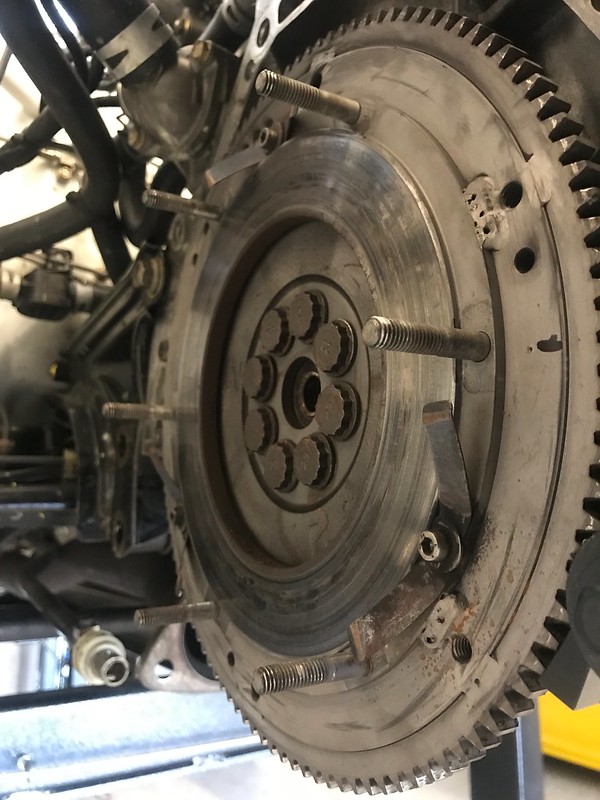

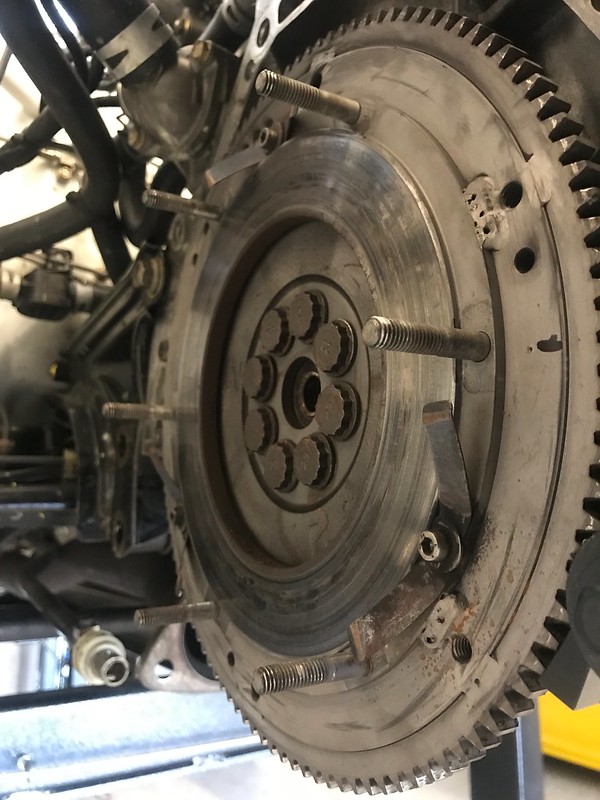

Modified OE Type R flywheel

ELR modified the OE Type R flywheel with mounting studs, anti-chatter springs and AP Racing single plate clutch and AP Racing billet stepped pressure plate and 4-puck rigid clutch disc. The entire assembly is almost the same weight as a regular clutch assembly due to the lightweight design of the clutch and clutch disc but paired with the heavier OE flywheel.

AP Racing clutch

The clutch and clutch disk are pretty trick piece. The design is similar to a Tilton or most other billet pressure plates and rigid clutch discs, however, the thickness and material of the disc is pretty beefy. Also (not shown) is a low profile release bearing that uses the OE fork and slave cylinder.

Special Hewland/WTI transmission

Interestingly I discovered that the Hewland transmission is actually a WTI transmission with a Hewland stamped case. The serial number on the case is sequentially close to my other spare Hewland transmission, however, it turns out that ELR replaced the Hewland internals with a custom WTI gearset that's designed towards Group N specifications. The WTI (clutch) differential is massive and heavily machined. The ring gear bolts have safety wire, the ring gear has lightening holes and the transmission case (both the bell housing and outer case) have been machined for clearance. The gear teeth have a slight radius and certain gears even have holes drilled into the teeth for lightening. Also the dog sliders feature four dogs per gear (my other transmissions use six dogs per gear) and the slider for 1-2 gear has been lightened with three holes been each dog for rapid deceleration when shifting. The forks are custom designed and are extra thick/large for durability. The transmission outer case was machined accordingly for the extra large fork size. The case was also modified for extra large and heavy duty shift detents, ball bearings and sealing plugs. Also the slider distance between certain gears was shortened to reduce throw and shift delay. Lastly, the shift change assembly was heavily modified with additional welds, strengthening rods, and reinforced shift selector arm. Interestingly the modifications done on this unit are similar to the modifications in my other Hewland transmissions and is similar (but a lot less advanced) to the modifications Speed Factory offers to it's customers. Included a picture showing the three different styles with the Speed Factory unit at the top, a new (circa 2000-2003) Hewland unit in the middle and the Hewland unit from this transmission (circa 1998).

Damaged passenger side axle

Upon removing the transmission from the car I discovered that the passenger side axle was stuck inside the transmission. Normally it wouldn't be that big of deal because you can just punch it out from the other side of the differential, however, this particular differential isn't see through so I had to remove the transmission with the axle attached and had to pry it out from the case. The case sustained some minor damage around the seal area but nothing a machine shop can't fix (in progress). Going forward I'll be using new upgraded "road race" axles like the yellow car uses.

Front and rear anti-roll bars and alternate sizes/thicknesses

I figured people would get kick out of seeing all various front and rear bars. I had to take some measurements for the suspension overhaul.

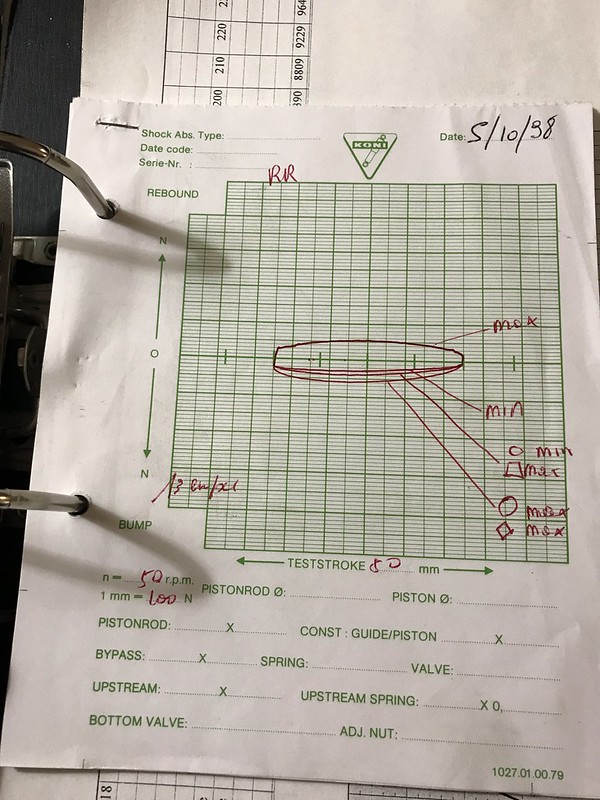

Penske suspension removed

Took about twenty minutes to remove (thank you air jacks). The suspension will be fully tested, disassembled, inspected and rebuilt with new parts where needed and retested before shipping back. The suspension hats, spacers, mounting points, valving, etc... was custom fabricated by ELR and Penske.

Carbon radiator & oil cooler ducting

Just a quick shot of the carbon ducting through the bumper. The picture doesn't do the system justice but it's still awesome looking.

Updated interior and exterior shots

I still haven't detailed the car, in fact I've only washed it once since July but wow does it look good!

Doweled cylinder head/intake manifold

As part of getting every ounce of power from this motor ELR/NBE doweled the cylinder head and intake manifold for perfect gasket alignment. Both the head and manifold showed signs of porting but it wasn't anything extreme as the FIA limited the shape and opening size within 2-4% of stock. I didn't snap a picture but even the throttle body shaft size was machined for improved airflow.

Modified OE Type R flywheel

ELR modified the OE Type R flywheel with mounting studs, anti-chatter springs and AP Racing single plate clutch and AP Racing billet stepped pressure plate and 4-puck rigid clutch disc. The entire assembly is almost the same weight as a regular clutch assembly due to the lightweight design of the clutch and clutch disc but paired with the heavier OE flywheel.

AP Racing clutch

The clutch and clutch disk are pretty trick piece. The design is similar to a Tilton or most other billet pressure plates and rigid clutch discs, however, the thickness and material of the disc is pretty beefy. Also (not shown) is a low profile release bearing that uses the OE fork and slave cylinder.

Special Hewland/WTI transmission

Interestingly I discovered that the Hewland transmission is actually a WTI transmission with a Hewland stamped case. The serial number on the case is sequentially close to my other spare Hewland transmission, however, it turns out that ELR replaced the Hewland internals with a custom WTI gearset that's designed towards Group N specifications. The WTI (clutch) differential is massive and heavily machined. The ring gear bolts have safety wire, the ring gear has lightening holes and the transmission case (both the bell housing and outer case) have been machined for clearance. The gear teeth have a slight radius and certain gears even have holes drilled into the teeth for lightening. Also the dog sliders feature four dogs per gear (my other transmissions use six dogs per gear) and the slider for 1-2 gear has been lightened with three holes been each dog for rapid deceleration when shifting. The forks are custom designed and are extra thick/large for durability. The transmission outer case was machined accordingly for the extra large fork size. The case was also modified for extra large and heavy duty shift detents, ball bearings and sealing plugs. Also the slider distance between certain gears was shortened to reduce throw and shift delay. Lastly, the shift change assembly was heavily modified with additional welds, strengthening rods, and reinforced shift selector arm. Interestingly the modifications done on this unit are similar to the modifications in my other Hewland transmissions and is similar (but a lot less advanced) to the modifications Speed Factory offers to it's customers. Included a picture showing the three different styles with the Speed Factory unit at the top, a new (circa 2000-2003) Hewland unit in the middle and the Hewland unit from this transmission (circa 1998).

Damaged passenger side axle

Upon removing the transmission from the car I discovered that the passenger side axle was stuck inside the transmission. Normally it wouldn't be that big of deal because you can just punch it out from the other side of the differential, however, this particular differential isn't see through so I had to remove the transmission with the axle attached and had to pry it out from the case. The case sustained some minor damage around the seal area but nothing a machine shop can't fix (in progress). Going forward I'll be using new upgraded "road race" axles like the yellow car uses.

Front and rear anti-roll bars and alternate sizes/thicknesses

I figured people would get kick out of seeing all various front and rear bars. I had to take some measurements for the suspension overhaul.

Penske suspension removed

Took about twenty minutes to remove (thank you air jacks). The suspension will be fully tested, disassembled, inspected and rebuilt with new parts where needed and retested before shipping back. The suspension hats, spacers, mounting points, valving, etc... was custom fabricated by ELR and Penske.

Carbon radiator & oil cooler ducting

Just a quick shot of the carbon ducting through the bumper. The picture doesn't do the system justice but it's still awesome looking.

Updated interior and exterior shots

I still haven't detailed the car, in fact I've only washed it once since July but wow does it look good!